Dates are at the heart of efficient supply chain planning. Customers require their goods or services to be delivered on a preferred date. This preferred date affects how the system will plan for making that stock or service available.

Within Dynamics NAV, there are a multitude of features that affect how the dates are handled. To ensure an efficient supply chain, these dates need to be understood and tracked.

I will use an example below to explain various dates for a supply chain cycle based on a purchased stock item.

Dates on The Sales Order

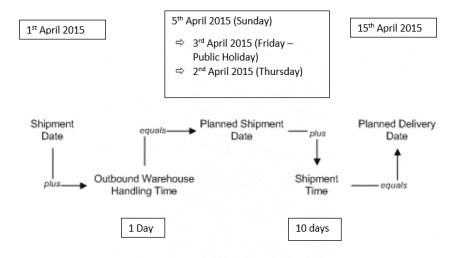

Let’s say a customer has requested the goods to be delivered on 15th April 2015. We shall call this: Planned Delivery Date.

There are two types of lead times that affect when the goods should leave the warehouse: Shipping Time – The time between when the items ship from the warehouse and when they arrive at the customer’s address. Outbound Whse. Handling Time – The time that is required to pick, pack, and label the items in an order.

Let’s say that the shipping time is 10 calendar days but the goods must leave on a week day and the outbound warehouse handling time is 1 weekday

Hence, our calculation for the date when the goods need to be available for picking is as follows:

Dates on the Purchase Order

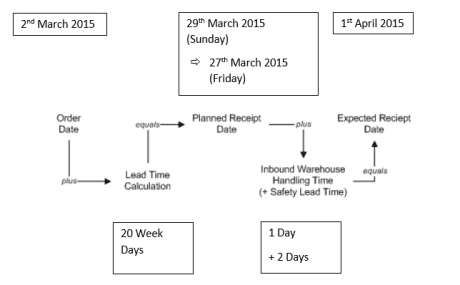

We will use 1st April 2015 as our target date for the availability of the goods. Since the stock item is a purchased item, we need to make sure that the goods are delivered well before 1st April so that we can do our internal processes before shipping the goods out.

The three lead times important at this stage are: Safety Lead Time – The buffer period if there are delays in the purchase replenishment lead time. This affects the date when the items are available for sale. Inbound Warehouse Handling Time – The time that is required to receive and put away the items of an order. Lead Time Calculation – The time between when the items are ordered from the vendor and when the items are received by the company. Alternatively, this is known as the vendor lead time.

Let’s say that our safety lead time is 2 week days and it takes 1 day for the warehouse personnel to label the stock and put it away in the warehouse.

The shipping time (or the lead time) is interpreted in the same way as the Sales Orders. It is the time from when the order is placed to when the goods are received.

So based on the above, our dates are as follows:

So based on this example, we need to place a purchase order on 2nd March 2015 if we are to successfully meet the customer delivery request for 15th April 2015.

Any changes in this supply chain cycle affect these dates. Meeting customer expectations requires careful planning and tracking at various levels of the supply chain. Dynamics NAV Planning Worksheets allow users to see the effects of these changes and re-plan orders if necessary. This provides significant time and cost savings and ensures a better customer experience.